General Layout

1. Mass flow dynamic simulation and mass flow study of iron & steel enterprises

The use of simulation platform and computer 3D dynamic simulation technology in the analysis and design of mass flow in iron & steel enterprises can help accomplish the feasibility study, optimization of mass flow solutions, and refinement of the system design. The vast amounts of data acquired from the system provide access to scientific design. The dynamic simulation analysis technology has been applied in the mass flow analysis of Zhanjiang iron & steel base, and a steel works in Brazil, to achieve optimal mass flow design, short process, reduced logistics costs and significant economic benefits.

2. Compact general layout technology for ironmaking and steelmaking workshops

The compact general layout and transportation system utilizes the new type molten iron transportation technique- "crane +straddle carrier". In this way, the compact layout technology changes the routine general design of iron and steel workshops, thus providing solutions to circumstances when there are no railways or roads available between large blast furnace ironmaking plants and steelmaking workshops. The compact layout technology is especially suited for small construction sites and projects in places inaccessible by rail. Currently, it has been applied in Chongqing steel environment-friendly relocation project and others, which resulted in lower energy consumption, less environment pollution, and optimal land utilization, thus creating more economic and environmental benefits for our society as well as enterprises.

3. Vertical design analysis technology

The analytical system for vertical design constructs digital elevation model on the basis of Bentley landform analysis platform, for further 3D terrain analysis on the building site. The vertical design technology has the functions of identification of disadvantageous hydrogeological regions, and rapid comparative analysis of design solutions. Hence, it is ideally suited for the construction of iron & steel plants in mountainous areas or complex terrain. The rapid landform and geological analysis can help optimize the design by making the best use of the hydrogeological conditions and thus reduce construction cost.

4. Economic evaluation system for greenfield projects

Economic Evaluation System Software for Construction Project prepared according to Economic Evaluation Methods and Parameters for Construction Project (the 3rd Edition)

Financial Analysis and Economic Evaluation suitable for industrial and non-industrial projects in China

The above have been successfully applied to the projects like Feasibility Study for Zhanjiang Iron & Steel Base, Plan for 10Mt/a Iron & Steel Base in Lianyungang.

5. Database of steel industry

The information database, serving as a complete, rapid and accurate support for consulting services, has been successfully applied to the projects for which CISDI has provided consulting services.

The consulting results which were validated in the projects have been supplemented to information database.

The information library provides

Documents and files

Skill improvement

Technological progress

Standardization

Mass balance

Video information of steel producers

Energy balance

Engineering market analysis report.

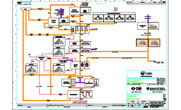

6. Plantwide coordination of process units

Proportioning calculations: Conducting proportioning calculations for sintering plants, pelletizing plants and blast furnaces according to the ores conditions.

Ramp-up calculations: Conducting coordination calculations between ironmaking & steelmaking plants and preparing the ramp-up curve according to the conditions of the different process units and start-up sequence.

Mass flow system: Overall mass flow diagram prepared with AutoCAD.

All of the above has been successfully applied to the consulting projects overseas.

Other Core Technology